Drop Tester distribution|drop test method : Big box store A drop test, or free fall test, simulates vertical and rotational impacts that can put goods at risk in the context of a distribution cycle, mainly during handling and storage. The drop impact test is performed in a laboratory context using Drop . WEBHere at The Jerk Off Games, we want to deliver a fun, immersive porn experience for our viewers. Each video has a different theme (sexy nurse, personal trainer, spying on your hot neighbour.), and each girl has a different style. Some are wet and sloppy with tons of spit, others are sexy and sensual. but these girls all know how to give an amazing blowjob! .

{plog:ftitle_list}

Resultado da 6 dias atrás · Encontros casuais Niteroi, se está procurando uma pessoa para um encontro casual tem encontrado o lugar onde a procurar. Procura amigos, procura amor, encontros casuais com casais, swingers, escorts lésbicas e homens para uma troca de casais em Niteroi.

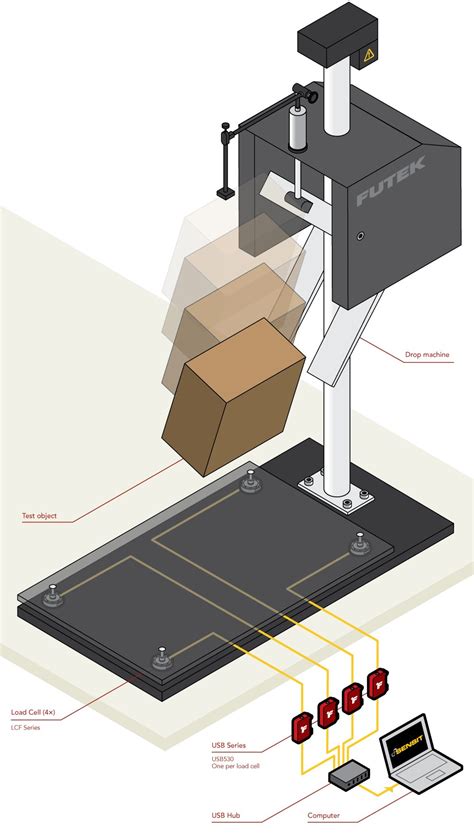

A drop tester enables product and packaging designers to examine how a product behaves when dropped from different heights, simulating various drop scenarios in a lab environment. Explore the core components of a Lansmont .

Westpak’s testing solutions help manufacturers assess their products throughout their lifecycle. With drop testing, Westpak can provide data-driven insights to uncover distribution and use patterns, as well as optimize product design, .In particular, the ASTM D5276 drop test: Allows manufacturers to assess the structural integrity of a product and/or packaging. Enables manufacturers to evaluate the type of packaging .Drop testers allow companies and laboratories to know how vertical and rotational impacts can affect the integrity of the packaging and the products. The information obtained by the innDrop family will help to design a suitable .A drop test, or free fall test, simulates vertical and rotational impacts that can put goods at risk in the context of a distribution cycle, mainly during handling and storage. The drop impact test is performed in a laboratory context using Drop .

Drop testing simulates the impacts that occurs during shipping and distribution environment. The information obtained by performing drop testing allows companies to save money, minimize damage and losses, while reducing costs .

Drop testing is a procedure used to evaluate the response of packaging and its contents to effects such as free drops, tumbles, and other types of handling in shipping and distribution environments.ASTM D5276 is a standard test method that outlines the procedure for testing loaded boxes, cylindrical containers, bags/sacks, and pouches by the free-fall drop method. For containers that are less than 110lbs (50 kg). This test will .

scratch test allergy cost

drop test standards for packaging

The ASTM D5276 standard outlines the procedure for performing drop testing by free fall of packaged products and shipping containers to determine their ability to withstand the normal .What is a drop test in packaging? Within one of the countries with the highest volume of merchandise exchange, such as the US, being able to conduct package drop testing becomes of utmost importance. These tests evaluate .Careless acts by any person in the distribution cycle. Packaging Drop Test Procedures. Keystone is an ISO 17025 accredited test laboratory capable of testing products to the package testing requirements of various drop testing standards. The .We perform drop testing to ISTA and ASTM standards as well as being able to run bespoke tests to ensure we can simulate manual handling and distribution scenarios. . Distribution Testing, Materials Science and Engineering United Kingdom Contact Sumeet James Raw. Operations Director of Packaging Testing, Materials Science and Engineering .

These drop test standards describe the process to perform free fall tests as well as tests to be performed in common distribution chains. In addition, drop tests are specified in various ISTA drop test procedures, including 1A, 1B, 1C, 1D, .Due to the size and weight, the drop test is suitable for the containers that are manually managed throughout the distribution cycle. The ASTM D5276 standard outlines the procedure for performing drop testing by free fall of packaged products and shipping containers to determine their ability to withstand the normal hazards of handling and .

This drop tester allows the simulation of falls and rotational impacts that can affect packages and products during their handling and distribution. Some of its features include: Several models adapted to the weight of the package, being able to test samples up to 1,200 kg or 60 lbs.ASTM D4169 utilizes different types of tests, such as drop testing, vibration testing, compression testing, and incline impact tests to evaluate a packaging system’s ability to withstand the distribution environment. This type of testing, categorized as transportation and distribution testing, is required for all shipping containers that .

L.A.B. Equipment, Inc., was established in 1933 and has been recognized for decades as the global leader in the design, manufacturing, and service of product reliability and package testing equipment. This includes drop testers, shock testers, hydraulic vibration, mechanical vibration, incline impact testers; and through our sister company .ISTA 6-Series: Developed in partnership with Amazon to simulate package delivery through Amazon’s distribution network. . Conducting the Drop Test: A drop testing machine or a free-fall method is used to ensure precise and repeatable drops. The method of dropping (manual or mechanical) should align with the standard being followed. .

These standards are further reinforced by various ISTA drop test procedures, including 1A, 1B, 1C, 1D, 1G, 1H, 2A, 2B, 2C, 3A, 3B, 3F, 3K, 4, and the 6-FEDEX and 6-SAMSCLUB series, each specifying specific drop testing methods tailored to different packaging scenarios.Drop testing simulates the impacts that occurs during shipping and distribution environment. The information obtained by performing drop testing allows companies to save money, minimize damage and losses, while reducing costs and ensuring customer satisfaction.Drop Testing aids us in the design of sturdy packaging that will not only protect the product from incurring damages if/when it is dropped during handling or transport, but the packaging will stand up to being dropped repeatedly, and it will continue to protect the product within after multiple drops. . Distribution Packaging Lab Vibration .

Throughout the delivery process, it’s likely that a products shipped on pallets will experience shocks of all types drop testing helps determine your pallets durability to shocks that can occur in the distribution supply chain. Drop Testing aids us in the design of sturdy pallets that will protect products from incurring damages if/when it is .It is also beneficial to perform this test to observe the failure of a container and the resulting damage to its contents. Scope of the ASTM D5276 Standard Test Method for Drop Testing. The ASTM D5276 standard is best suited for containers that are typically manually handled at some point throughout the distribution cycle.Precision drop testing at an affordable price. The TrueDrop™ 160 drop tester. This drop tester represents the ultimate in product and package performance testing and is designed to meet a wide variety of global testing needs. View More Details. Get a QuoteGlobal Distribution of Drop Tester Manufacturers by Country Categories Related to Drop Testers. Impact Testers What Is a Drop Tester? A drop tester is a device that allows a test object to be dropped spontaneously while repeatedly maintaining a specified height and other conditions in order to determine the impact and effects of dropping the .

In ISTA 2A drop test height varies with package-product weight. For ISTA 2B drop test, the test level determinate 6 in (150 mm). In the case of ISTA 2C drop test, height of the drop varies for package-product weight (and Distribution channel). Less than 50 lb (23 kg), 50 lb (23 kg) to 100 lb (45 kg) Greater than 100 lb (45 kg).We perform drop testing to ISTA and ASTM standards as well as being able to run bespoke tests to ensure we can simulate manual handling and distribution scenarios. . Distribution Testing, Materials Science and Engineering United . Drop Test, Advanced Packaging Technology LaboratoriesThe most vital packaging development consideration in distribution packaging is determining the probabil.

A Comprehensive Guide to Drop Testing – E-commerce has grown dramatically in recent years, with tons of products being shipped and delivered around the world every day. Therefore, more and more companies are aware of the importance of guaranteeing that their products can withstand the rigors of transport and handling to reach end customers in optimal conditions.This optimization is crucial in an era where sustainability and cost-effectiveness are paramount. Moreover, drop testing helps in complying with industry standards set by organizations like ISTA and ASTM, ensuring that packaging meets or exceeds the rigorous requirements of global shipping and handling conditions. As e-commerce and global distribution continue to grow, .Distribution testing Apply for package testing Parcel . Rotational corner drop. Drop. Incline impact. Rotational edge drop. Vibration with top load. Concentrated impact. Bridge impact. Hazard impact. Forklift handling. download ISTA 3B details

Products » Drop Test Systems » AccuDrop™ 125. AccuDrop™ 125. The AccuDrop 125 provides the same precision drop testing technology as the other AccuDrop series products but is meant for smaller packages. The AD-125 is an intuitive and affordable option for package performance testing. View More Details. Get a Quote. Description;Distribution testing Distribution testing involves some combination of drop, compression, vibration, shock/impact, and climatic condition. This testing is intended to simulate specific distribution environments by maintaining a controlled, repeatable setting in a laboratory so that packages can be evaluated according to industry standards.3. Drop Test Example Instron is a well-known leader in advanced material and component testing techniques. They supply instrumentation, support services and expertise for testing materials, products and structures. [2] Test engineers needed to develop an impact test machine for automotive bumper testing.Features. Hydraulic Lift System with Multiple-Tine Drop Carriage configured for a variety of products. 500 lbs (227 kg) maximum payload capacity; 48” W x 30” D (1219x 762 mm) steel impact surface – Standard size – (custom available) 2” – 48” (51- 1200mm) adjustable drop height Standard drop system – (custom heights available) Fully Automated Operator Control .

scratch test assay

Drop tester. The drop tester simulates drops and rotational impacts that affect the packages and products during handling and distribution. In order to perform the drop tests outlined in the procedure, we will also need certain hazards, such as a block or a box.

Precision Drop Tester Drop on Hazard Hazard Drops In reality, not all items are dropped on flat, laboratory-style floors. In fact, some small parcel distribution tests require drops to occur on a predetermined hazard. Bare Product Drop Product Drops Lansmont customers use drop testers to perform bare product drop testing to simulate in-use events

drop test standard

scratch test assessment

drop test quick release

Resultado da downyy (@ddwrkk_) บน TikTok |604.4K ถูกใจผู้ติดตาม 65.2K คนig downy.babyy.ดูวิดีโอใหม่ล่าสุดจาก downyy (@ddwrkk_)

Drop Tester distribution|drop test method